Product Line

- home

- Products

- Product Line

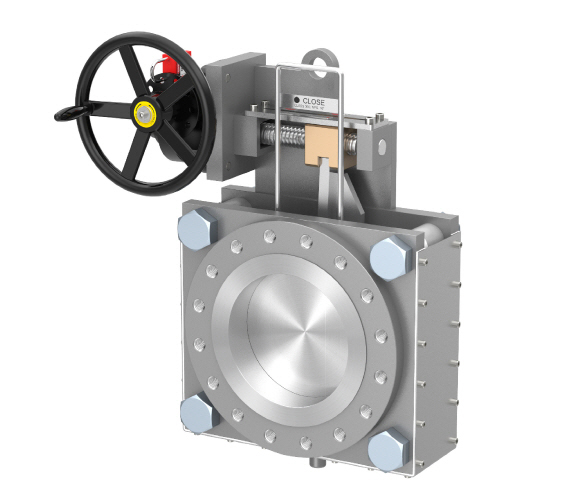

Sliding Type

Sliding type line blind has a unique gear set mechanism that makes a gap to slide in/out a blind plate without pipe joint stretching. It provides a safe and time efficient blinding process. SAMMI’s sturdy and simple design creates highly reliable and durable line blinds using the most advanced technology

READ MORE

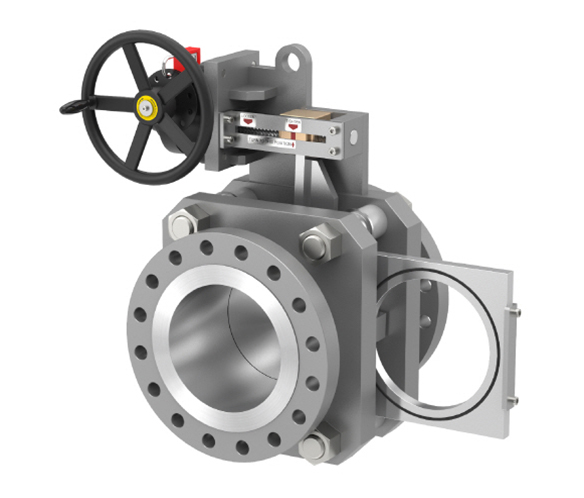

SWING TYPE

Swing type line blind is one of the most popular line blinds that an operator can use to quickly and efficiently isolate a pipeline safely. SAMMI’s unique design provides non-stretching operation that can prevent pipe joint stress caused by stretching movement.

READ MORE

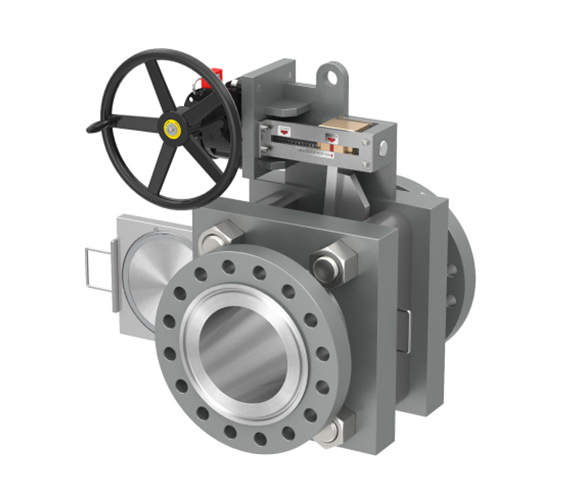

COMPACT TYPE

Compact type line blind is designed for replacing an existing valve with limited F-F distance, large diameter pipeline or limited space installation. SAMMI’s compact design provides weight reduction and removes the need for extra pipe supports.

READ MORE

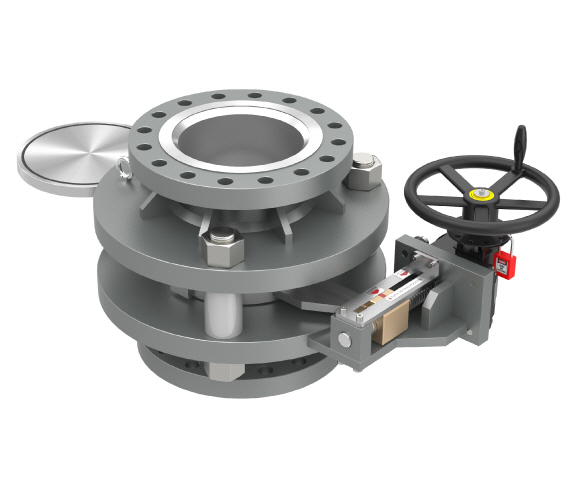

NON-SPILL TYPE

Non-Spill type line blind has many advantages in oil terminal and offshore applications where the space of installation is limited and prohibiting of pollution is strictly required. With SAMMI’s unique design, this line blind can prevent ground pollution and be installed parallel to the pipeline.

READ MORE

JACK BOLT TYPE

Jack Bolt type line blind has been used for a long time as it is applicable for a broad range of pressure pipelines with a lower cost. To change the blind plate position, an operator is required to unbolt it manually.

READ MORE

GOGGLE TYPE

Goggle type line blind is a good solution to isolate large diameter, high temperature and/or toxic gas pipelines for maintenance and inspection.

READ MORE

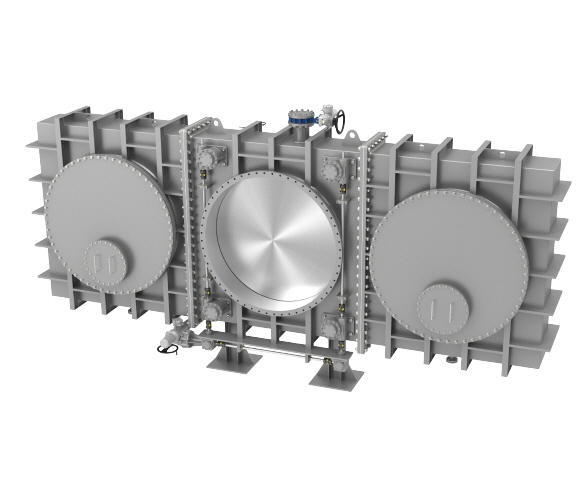

AUTOMATED LINE BLIND

Automated Line Blind is good for remotely controlled blinding operation, high frequency of on-off cycle and/or critical fluid application. SAMMI Lind Blind provides automated blinding system by AOV, MOV or oil hydraulic source.

READ MORE

EX TYPE

EX type Line blind offers 100% pipe isolation for severe service conditions such as extremely high temperature, cryogenic, gas/liquid contained particles and/or polymer production pipeline. The unique stretching mechanism creates a gap to switch blind plate positions quickly and efficiently.

READ MORE